|

A-Zoom Aluminum Snap-Caps |  |

|

|

|

|

CRUFFLER.COM

presents

ACCESSORY

REVIEW,

February

2001:

|

A-Zoom Aluminum Snap-Caps |  |

| Practice

makes perfect, or so it is said. The old adage is amply true with

respect to firearms. The only way to become proficient at loading,

drawing, aiming, firing, and unloading a firearm is by constant repetition.

Such proficiency is a perishable skill; the repetitive training must be

an ongoing affair. The problem is that training in a realistic manner

requires the use of live ammunition or an ammunition surrogate. The

use of live ammunition for other than actual firing poses a significant

risk of harm from unintentional discharges, and is therefore to be avoided.

The benefits of dry firing, the practice of operating a firearm's firing mechanism in |

|

The question becomes one of how to practice gun handling and dry firing in a manner that is safe but realistic. The answer is to use a snap cap. A snap-cap is a cartridge shaped piece that can be cycled through the firearm's mechanism and chamber. They are caliber specific, and usually contain some sort of shock absorption mechanism that cushions the firing pin's fall. Snap-caps are made of materials ranging from plastic to rubber to brass to aluminum, and have shock absorption systems such as spring loaded pins or polyurethane plugs.

NOT ALL

SNAP-CAPS ARE CREATED EQUAL

Up until 1997

or 1998, shooters were limited in their options. Reloaders were able

to use inert components to assemble dummy cartridges, but these posed significant

risks as they were easily confused with live ammunition. The only

readily available snap caps were manufactured by Armsport. These

were made of plastic with a spring loaded "primer," (see CRUFFLER.COM

Accessory

Review, March 2000). Unfortunately, the Armsport snap-caps had

a tendency to break after only a very little use. Worse, they fractured

into very small pieces that often became lodged in guns' mechanisms and

could cause serious damage.

One shooter who ran afoul of the Armsport snap caps was Gary Hunt. Gary began to shoot in 1995, and rapidly became an avid pistol and revolver enthusiast. When teaching a new shooter, Gary decided to use the Armsport snap-caps in preference to live ammunition. In the process of loading, firing, and unloading, one of the snap-caps disintegrated, and a small piece lodged within the mechanism of the gun. No amount of coaxing would remove the piece, and the gun had to eventually be sent to a gunsmith for repair. Normally, the shooter is without recourse in such a case. But then, normally the shooter isn't the owner of a manufacturing facility! Gary Hunt is the owner of Ready Products, which had been manufacturing precision automotive components since 1976. Addressing the problem as a machinist, Gary set out to create a snap-cap that would be durable, readily distinguishable from live ammunition, and that would not harm the firearm.

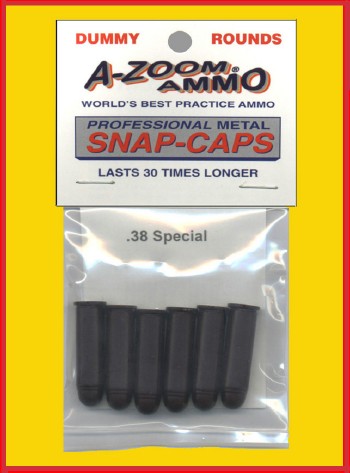

The result of his efforts was the first A-Zoom Snap-Cap. Since 1998, A-Zoom (a subsidiary of Ready Products) has been making snap-caps on CNC machinery from solid 6061 aluminum alloy. They have a dark red hard anodized finish and a

|

"primer" made from a patented polyurethane formula. The advantages of this construction are manifest. There's the innate durability of the aluminum and the fact that there are no parts to break off and become lodged in the gun. There's the hard anodizing which ensures that no shards of aluminum will shave off to foul the firearm. There's that fact that the mass of the snap cap begins to approach that of a loaded round, adding realism to training scenarios. All of which adds up to a recipe for a very successful product. How successful, you ask? Today there are over 135 calibers represented in the A-Zoom product line. They run the gamut from the ubiquitous 9mm Luger, .45 ACP, and .357 Magnum to such rarities as .455 Webley, .505 Gibbs, 7x64mm Brenneke, |

All A-Zoom Snap caps are made to minimum SAAMI or, when applicable CIP, cartridge dimensions to ensure the widest possible firearm compatibility.

Field Test

The A-Zoom

Snap-Caps had an impressive resume, and we were eager to see if they would

stand up to the rigors of use. To this end, we ordered a representative

sample of calibers, to include:

Each snap-cap was to be "snapped," or cycled 1,000 times, or until the cap failed, and then inspected for wear. Our testing battery consisted of the following firearms:

- .41 Magnum (6 per pack)

- .45 ACP (5 per pack)

- .45 Long Colt (6 per pack)

- 7.62x39mm (2 per pack)

- .308 Winchester/7.62mm NATO (2 per pack)

- 12 Gauge

|

|

|||

|

|

|

|

|

|

|

S&W M657 |

|

|

|

|

|

|

|

|

|

Colt Government Model Astra A-100 |

|

|

|

|

AK-103 |

|

|

|

|

M444 L1A1 CETME |

|

|

|

|

Ithaca 37 |

|

|

In all cases, the primer composition showed little or no evidence of wear.

Conclusion

Were we sold? Oh yes!

We only wished that all of our equipment functioned this well, and was

as durable. A-Zoom makes a superior product. Whether you're

training or seeking to determine whether an action works as it should,

we are not aware of a better product on the market for those purposes.

A-Zoom Snap-Caps are simply the best we've seen.

And now, our

Buy-O-Meter rating for the A-Zoom Snap-Caps:

|