|

The Degtyarev "DP" Light Machinegun |  |

|

|

|

|

CRUFFLER.COM

presents

HISTORIC

FIREARM OF THE MONTH,

March 2001:

|

The Degtyarev "DP" Light Machinegun |  |

Degtyarev DP Light Machinegun Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 141 |

SPECIFICATIONS

Type: Light Machinegun System of Operation: Gas Caliber: 7.62x54mmR Capacity: 49 or 47 round pan Sights front: Blade Sights, rear: U-notch Length: 49.84" Weight (loaded): 18.48 lbs Barrel: 21", 4 grooves, right hand twist |

The Eastern Front was the only place where World War One was fought in a manner that the combatants anticipated. While the war in the west was a stalemate, where movement was measured in tens of meters and yards, the fighting in the east was marked by sweeping maneuvers over vast tracts of land. As always, combat exposed and highlighted the deficiencies of the weapons carried and used by the troops. One of the most crucial needs identified was that of making the light machinegun mobile enough to be carried forward with advancing troops so as to directly support an attack. To meet this need, the light machinegun had to be capable of being fired from the hip and shoulder as well as prone. It had to be brought into action instantly, and be capable of sustained fire. The first man to design a weapon capable of meeting these requirements for the Soviet Union was Vasily Alexeevich Degtyarev.

Vasily Alexeevich Degtyarev

| Degtyarev

was born in 1880 in Tula, heir to a long line of gunsmiths. At age

eleven he began working in the Imperial Ordnance Factory in Tula.

Ten years later, in 1901, he was drafted into the Russian Army and set

to work in an arms workshop at the military academy at Oranienbaum.

He was discharged in 1906, and went to work under the tutelage of Vladimir

Fedorov on the design of the first Russian avtomat (automatic rifle).

Prototypes of the rifle were made by hand in the workshops at Oranienbaum,

and work continued at the Imperial Ordnance Factory at Sestroryetsk.

In 1916, Degtyarev designed a selective fire carbine. This was a

seminal work, as the basic design elements of this weapon would be incorporated

into his later, and more successful automatic weapons.

Degtyarev's 1916 carbine, in contrast to most successful automatic designs of the period which were recoil operated, was gas operated. Breech locking was achieved by swinging lugs on the sides of the bolt into recesses in the receiver, and the recoil spring was located around a guide rod attached to the top of the receiver, acting on a projection of the bolt. The 6.5x50mm cartridges were stored in an integral five round magazine. Fully loaded the gun weighed only 8.5 pounds. |

Vasily Degtyarev in 1904 Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 136 |

Light Machinegun Development

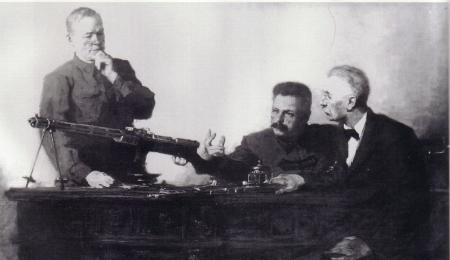

M.V. Frunze with V.A. Degtyarev and V.G. Fedorov in 1924 Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 138 |

In 1923, Degtyarev began to work on the design of a light machinegun. Initially, work was begun without the support of the main artillery administration (GAU). At the time, those in the know at the GAU looked down upon the portable machinegun as a temporary phenomenon that would always be inferior to the mounted heavy machinegun. The Degtyarev light machinegun got a significant boost in July, 1924. On the 22nd of that month, Nikolai Kuybishev, chairman of the Red Army Small Arms Committee, had the weapon formally tested. The resulting report praised "the outstanding originality of the idea, the great operational reliability and fire rapidity, and the simple handling of Comrade Degtyarev's system." As a result, Degtyarev and Vasily Fedorov were summoned by then |

In a 1957 interview, Vladimir Fedorov recalled the conversation:

M.V. Frunze was not only an expert who brilliantly understood and praised good weapons. . . he could also foresee their development far ahead, and, like no other officer I have ever encountered, could discuss with us designers all facets of the international situation, the tasks we were facing, the difficulties we had, or the potential of our military industry. He knew about everyone involved with small arms and had a good idea of their potential.As a result of the meeting with Frunze, the GAU proposed to the administration of the Weapon and Machine Gun Trust that all efforts should be

turned toward the Degtyarev light machinegun in view of the necessity to complete work. . . in the shortest time possible. The competition to develop automatic rifles is also an urgent job; however this work must be undertaken only after that on the Degtyarev light machinegun.

| Degtyarev completed the prototype in 1926, thanks in no small part to the direct involvement of Vladimir Fedorov. Other members of the design team included Gavriil Markov, Pavel Ivanov, Ivan Dolgushev, Evgeniy Aleksandrovich, Georgiy Shpagin, Sergei Simonov, Aleksei Kuznetsov, David Uraznov, Yakov Sukhanov, Ivan Bezrukov, Iosif Solovev, Pavel Dmitriev, and Nikolay Efimov. The prototype was gas operated, with the breech being locked by two retracting lugs on the bolt body that entered corresponding recesses in the receiver. The gun was striker fired, and functioned fully automatically only. Ammunition was fed from a top mounted pan magazine that contained 49 cartridges, but later this was reduced to 47. Sights were graduated to 1,500m, and a bipod was mounted near the barrel's midpoint. Additionally, and probably more importantly from the user perspective, the Degtyarev was easy to strip and reassemble. |

Vasily Degtyarev and Prototype DP Light Machinegun Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 140 |

When it was

introduced, the Degtyarev was something of a manufacturing marvel.

For comparison's sake, manufacture of the Maxim-Tokarev machinegun required

some 2,080 working patterns, 944 control patterns, 1,158 tool sets, and

400 different gauges. The Degtyarev required only 800 working patterns,

250 control patterns, 400 tool sets and the same number of gauges.

As a result, the Degtyarev was significantly quicker to manufacture than

other Soviet automatic weapons, as this tabular excerpt from a 1926 report

made by Vladimir Fedorov to the chairman of the Artillery Committee demonstrates:

|

|

|

|

|

| M1910 Maxim Heavy Machinegun |

|

|

|

| M1910 Maxim Mount |

|

|

|

| Experimental Fedorov-Degtyarev Light Machinegun |

|

|

1,005 |

| Fedorov-Degtyarev Light Machinegun Bipod |

|

|

67 |

| Degtyarev Machinegun |

|

|

|

| Degtyarev Machinegun Bipod |

|

|

|

| M1891 Mosin-Nagant Rifle |

|

|

|

| M1895 Nagant Revolver |

|

|

|

As can be seen, the time required to manufacture one Degtyarev was forty percent less than that needed for the Fedorov light machinegun, and it required only half as many pattern measurements and machining operations as a revolver and only a third as many as an infantry rifle.

Degtyarev's light machinegun development was not taking place in a vacuum. At the same time, Steyr, Vickers, and Colt were all offering machineguns to the Soviets. By and large, these were all First World War or earlier designs whose time had come and gone. Indeed, upon review, the GAU noted that "in view of the fact that these models are outdated in regard to their simplicity and ballistics, and also that our factories can produce much better weaponry, the proposed contracts should be declined." This view was shared by Sergei Kamenev, then the Red Army's supreme commander, who wrote "We have designed a new Russian machinegun which equals the most modern European ones."

Light Machinegun

Trials

In September

1926, the first series of trials including the Degtyarev were held.

Two guns were tested with about 5,000 rounds of ammunition. There

were several broken extractors and firing pins. Additionally, the

guns were noted as being particularly sensitive to dust. As a result,

the guns were sent back to Degtyarev for further refinement. In subsequent

trials in November 1926, 20,000 rounds were fired from each of the two

prototypes. After every three hundred rounds, the guns were dunked

in water to cool them. After every six hundred rounds, the chambers

and bolt carriers were lubricated. One of the two was then allowed

to fire 2,646 rounds dry so as to determine the importance of lubrication,

with no stoppages observed. Barrel endurance was tested by firing

twelve full magazines with no cooling time between magazine changes.

No bore erosion was observed.

During the 40,000 rounds fired, some sixty stoppages were noted, most being failures to eject, failures to feed, and other miscellaneous jams. Three bolt carriers, two recoil springs, and two bolt handles were broken during the trials. There were also a series of minor shortcomings: Rivet failures, the back plate latch and the pin connecting the the gas piston head to the body worked loose, the riveted barrel spacer came apart, and the casing bolt worked loose. Despite these shortcomings, it was determined that the basic gun, and the principles upon which it operated were sound. On December 29th, 1926, the GAU noted that "by the two aforementioned specimens of the Degtyarev light machinegun, the committee decided that these results - although generally satisfactory - indicate the necessity to strengthen some parts and refine the entire pattern, owing to the breakages and stoppages observed when firing." The guns were again returned to Degtyarev for further refinement. Final trials were scheduled for January 10th, 1927.

The latest series of refinements included strengthening the bolt, reinforcing the bolt handle and ejection port ribs, and altering the shape of the firing pin. Major components that had been determined to have been too weak (bolt carrier, extractor and gas piston rod) were manufactured from chrome-nickel steel. The trials were held between January 17th and 21st, 1927 at the firing range at the Tula Ordnance Factory. Again, 20,000 rounds were fired per gun. The results were impressive - one gun having a stoppage rate of 0.5 percent and the other 0.3 percent. However, the guns' heating during shooting burned the gas tubes, and the extractor hooks were destroyed. In one of the guns, the extractor spring tore away and the recoil spring failed. In summarizing the results of the trials, the GAU wrote:

Taking into account the percentage of stoppages (0.3 - 0.5%) and that 40,000 shots had been fired during the test, the amount of sundry breakages was minimal. As their character, as explained above, does not raise concerns about the durability of the machinegun, the commission considers it possible to accept these two machineguns as a pattern for production. However, the commission considers it necessary to draw attention to the fact that in the course of the tests the machineguns needed minor adjustments arising from the stoppages. In order to simplify production of the machinegun and make it more convenient to handle, the design bureau should be ordered to conduct special research in these directions. Perhaps a retarder can be introduced to slow the unlocking of the bolt to ease extraction of the empty cartridge case.Consequently, the GAU placed an order for a hundred Degtyarev guns, modified accordingly:

One gun in ten was tested for accuracy by firing ten single shots at a 100m target. The fifty percent dispersion radius was not to exceed 6 cm. This test was repeated for any barrel that failed to meet this requirement. If the barrel again failed, all guns and barrels in the lot were tested individually. To ensure spare parts interchangeability, two percent of all guns were tested by firing one hundred rounds automatically with spares in place. Only those spares that caused no difficulties were approved.

These acceptance tests provided the model for all subsequent Soviet small arms. More interestingly, these standards were put into place at a time when the phrase "Soviet industry" was all but oxymoronic. Most factories had obsolete or worn out machinery, and no domestic machine tool industry existed. There was neither capital nor opportunity to import machine tools. The labor pool of skilled workers was incredibly small. It is a testament to Degtyarev's design that his gun was able to be built in such an environment and that it passed the acceptance tests in spite of it!

Comparison testing against other domestic and foreign designs began in the summer of 1927. Chosen for comparison were the German Dreyse and the Maxim-Tokarev. The tests were witnessed by, among others, the Red Army's commander, Sergei Kamenev. Kamenev wrote:

Yesterday, in my presence, the Dreyse machinegun for the 3-line cartridge was tested. The tests were conducted in parallel, the Dreyse model being compared with our Degtyarev machinegun and the lightened Tokarev-Maxim model. The comparison yielded the following results: the best was clearly our Degtyarev machinegun, followed by the Dreyse and - in third place - the Tokarev- Maxim model. It is now evident that we have outdone the Germans, as our Degtyarev machinegun is far better than their Dreyse."However, there were still more tests to be conducted before full issue of the Degtyarev could commence. As the Soviet Artillery Chief, Marshal Nikolai Voronov put it: "It is not by chance that a prominent foreign engineer, having observed our testing, exclaimed "Well, we can now say that if a model has passed Russian tests, it will survive any war"." Typical of the tests was that conducted from September 5th to 7th, 1927. In that test, some 14,000 rounds were fired from one gun, and 8,526 from another. The testers noted that "results of the recent tests show that separate parts and assemblies of this machinegun are in need of additional perfection and research in the factory design bureau. In addition, the clearance between the tube and the gas piston and the diameter of the regulator holes must be adjusted: this must be applied retrospectively to the first batch, which has already been made." During this test, the bolt carrier had broken twice, and Degtyarev suggested that it be strengthened by narrowing the trigger slot and placing radial ribs into the rear part of the groove in which the locking lugs reciprocated. This change was approved by the GAU on October 5th 1927. With all the changes to the various sub-assemblies completed, the Red Army was presented with the first group of Degtyarev guns on November 12th, 1927, and the original one hundred gun order was filled in early January 1928.

Determined to provide the Red Army with the Degtyarev gun as soon as possible, the Revolutionary Military Council issued instructions to order another 2,500 guns in the 1927/1928 fiscal year. Manufacture was to start immediately without waiting for the customary troop trials, with the understanding that full interchangeability would not be required if it would delay deliveries. The creation of a production line was immediately begun at the Korovov Machinegun Factory. This decision to go ahead with series production even as troop trials were being conducted demonstrated great faith in the basic design. More pragmatically, it was also a military necessity if the Red Army was not to lack light machineguns in time of crisis. On December 21st, 1927, two Degtyarevs were tested in temperatures reaching -30 degrees Centigrade. One fired 1,500 rounds with neither cooling nor lubrication, while the other fired five hundred times. The testing committee recommended the adoption of the Degtyarev gun under the designation "Degtyareva Pekhtonii" (DP or, Degtyarev Infantry). The guns then began to reach the Red Army in large numbers. In addition to the original order for 2,500, 6,500 more were ordered in 1928/1929 (4,000 infantry, 2,000 aircraft, and 500 tank guns).

Production

Improvements

A great deal

of effort went into ensuring parts interchangeability, and on June 15th,

1928, the Deputy Chairman of the Revolutionary Military Council, Iosif

Unshlicht, held a meeting with representatives of the Chief Military Industrial

Directorate to discuss the possibility of accelerating the production of

guns with interchangeable parts, with a deadline being set for this production

of not later than early 1930. One result of the interchangeability

program was increased durability. The heat treatment was changed,

and the steels used in production were improved. From March 25th

to April 2nd, 1930, under direct orders of the Deputy Director of Armament,

Nikolai Efimov, thirteen DP's were tested in an effort to determine the

critical limits for the gun and its components. Shooting in this

test was done in two ways. Some of the guns fired bursts of eight

to ten rounds and were cooled after every third magazine, while others

fired bursts of ten to fifteen rounds and were cooled after every fifth

magazine. The guns were all lubricated after 1,500 rounds had been

fired, then cleaned, examined, and tested for accuracy after 3,000.

This test consumed some 573,000 rounds of ammunition, with the total per

gun ranging from 33,000 to 69,000.

By May 29th, 1930, Vladimir Fedorov wrote that the overall system durability had been increased to between 75,000 and 100,000 rounds, and that the critical parts which had been prone to breakage (firing pins and extractors) had been improved to a service life of between 25,000 to 30,000 rounds. This was a new milestone in Soviet automatic weapons development. Indeed, while making a speech to the Moscow garrison, Marshal Klimenti Voroshilov was moved to comment that "the machinegun problem has been solved principally by constructor Degtyarev, together with other designers. Our army is greatly indebted to him." Indeed, no less a publication than the American Rifleman magazine commented that "typical of the improvements which might have some importance for would-be riflemen could be considered the efficient system of breech locking applied to the Degtyarev light machinegun, and its further perfection. It is so absolutely simple that the cleverness of its designer cannot yet be entirely fathomed."

Service

Modifications

Clever or

not, the DP was continually upgraded with design improvements.

1931 Model DP Light Machinegun Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 145 |

The

1931 pattern light machinegun omitted the barrel jacket. The gas

tube was moved to the rear until it lay directly in front of the receiver.

This shortened the piston rod. The recoil spring was moved to a tube

screwed into the rear of the receiver, and it thus projected backward above

the butt. A safety mechanism was added to the right side of the trigger,

and the firing pin was lengthened to serve as a recoil spring guide rod.

The 1934 pattern had the gas tube moved to the |

| The 1938 pattern had several noteworthy changes. The magazine pan was replaced with a hopper. Loose cartridges were fed into the hopper from above and pressed downward by a spring, and forced into the feedway by a lever on the left wall of the hopper. This method was a direct result of Soviet encounters with Japanese guns that used this feed mechanism during the Khalkhin Gol battles in 1937 and 1938. |

1938 Model DP Light Machinegun Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 145 |

DPM Light Machinegun Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 146 |

longitudinal rotation to aid in leveling the gun. This modernization program was supervised by Degtyarev himself with assistance from Aleksandr Belyaev, Aleksandr Skvortsov, Aleksei Dubynin and Petr Polyakov. On August 29th, 1944, the new gun was presented to the State Defense Committee by the GAU, and adopted as the Degtyareva Pekhtonii Modernizirovannii (DPM - Degtyarev Infantry, Modernized.) The DPM represented a marked improvement in reliability, stability, handling characteristics, and accuracy over the DP. |

Conclusion

The DP and

DPM served the Red Army well during World War Two. The weapon had

been in service for over a decade, and the troops were well aware of how

to maximize the gun's capabilities. However, while the DP and the

DPM were at least as good as their foreign contemporaries, wartime usage

demonstrated significant shortcomings. Small unit maneuverability

was constantly increasing, and in this light, the large size and weight

of the DP/DPM reduced their utility. The blame for this fell principally

on the pan magazine, which weighed in excess of three and a half pounds.

The magazine's design had been dictated by the rimmed 7.62x54mmR rifle

cartridge, which caused rim over rim jams in conventional box magazines.

The small capacity of even comparatively large pan magazines limited the

guns' practical rate of fire and prevented the use of long bursts.

As a result, several attempts were made to modify the gun for belt feed,

but none of these was perfected during the war. The belt fed Degtyarevs

weighed as much as twenty-seven pounds and the hanging belt made running

with the gun difficult. As one Soviet report put it, "The belt feed

for the light machinegun is a serious problem requiring profound investigation.

Until now, the question of the best way of feeding machineguns with cartridges,

from a belt or a magazine has not been answered."

| The question would not fully be answered for the Soviets until the advent of the M1943 7.62x39mm cartridge, and another Degtyarev design, the RPD. |

DP Light Machinegun in Action Image Credit: Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995) Page 148 |

BIBLIOGRAPHY

Bolotin, D.N., Soviet Small Arms and Ammunition, (Finnish Arms Museum Foundation, Hyvinkaa, Finland: 1995)

Soviet Small

Arms and Ammunition is available from IDSA Books. Click on the

image to order: