|

The Martini-Henry Rifle |  |

|

|

|

|

CRUFFLER.COM

presents

HISTORIC

FIREARM OF THE MONTH,

September

2000:

|

The Martini-Henry Rifle |  |

Image credit: http://www.angelfire.com/vt/milsurp/ |

SPECIFICATIONS,

MARK II RIFLE

Type: Single Shot Breech Loading Rifle System of Operation: Lever Actuated Falling Block Caliber: .577/.450 Capacity: Single Shot Sights front: Blade Sights, rear: Notch Length: 49.5" (Long Butt) Weight (unloaded): 8lbs. 10.5 ozs. Barrel: 33.187" Rifling: Seven grooves, right hand twist, 1:22" |

The developmental history of the Martini-Henry rifle is something of a marvel. In the space of six years, the British ordnance establishment brought to fruition a rifle that was the sum of many parts and many different ideas. It was born in the nascent days of the self-contained metallic cartridge, and soldiered on well into the time of the small-bore smokeless powder era. The Martini-Henry became the benchmark for single-shot breech loading firearms, and even today the action commands respect at long range target shoots. Few, if any other designs can lay claim to the simplicity, robustness, and reliability of the Martini-Henry.

HISTORY

While the

Danish-Prussian War of 1864 was a mere footnote on the Atlantic's western

shores, being overshadowed by the American War Between the States, it garnered

significant attention in Europe. In the short but decisive conflict

the Prussians were armed with one of the first breech loading rifles to

be used in large numbers by any army, specifically the Dreyse Needle Gun.

The Needle Gun was an indifferent example of a breech loader, but it had

proven its worth sufficiently so as to encourage other nations to adopt

breech loading rifle systems. Reaction in Britain was rapid.

The Secretary of State for War, Lord de Grey and Ripon, established an

Ordnance Select Committee (OSC) to report on the desirability of arming

the British infantry with breech loading rifles. The OSC turned in

its final report on July 11, 1864 in favor of arming the infantry completely

with breech loading rifles. This was the death knell of the muzzle

loader in British service.

The OSC carefully considered the requirements and parameters of the new breech loading arms giving special attention to the questions of barrel length, caliber, weights of both rifle and ammunition, the nature of the cartridge and the mode of ignition, and the system of rifling and the rate of twist. On February 1, 1865, the OSC recommended that the caliber be .450", the barrel have a length of 39", the weight of the rifle without bayonet not exceed nine pounds, the bullet to weigh 480 grains with a 70 grain charge, and the cartridge to carry its own means of ignition. Rifling characteristics were to be left to the discretion of the gunmaker. With these requirements in hand, Major-General St. George, the Director of Ordnance issued an advertisement to "Gunmakers and Others" announcing a competition for the production of the best military breech-loading rifle on June 21, 1865. The arm sought was described in the advertisement as follows:

1. Calibre - 0.450-inches. High gauge rejecting plug, 0.453-inches.Each competitor was required to furnish specifications, drawings, cost estimates, a specimen rifle, and 20 rounds of ammunition to the Director of Ordnance at the War Office in Pall Mall, London by September 30, 1865. Upon inspection the OSC would choose those rifles that seemed of sufficient promise, and upon notification of this selection, the manufacturers of the selected rifles were to supply six more rifles, each in strict conformity to the specimen previously submitted along with 9,000 rounds of ammunition. Reimbursement for the six rifles and ammunition was to be the munificent sum of £70.

2. Barrel - Length, 39.0 inches.

3. Barrel - Weight, 4 lbs. 8 ozs. to 5 lbs.4. Twist - Optional

5. System of grooving - Optional

6. Musket, with cleaning rod or ramrod, but without bayonet - weight not

to exceed 9 lbs.

7. Bullet - Weight, 480 grains.

8. Charge - Not to exceed 70 grain J2 Government Powder.

9. Cartridge - By preference to carry its own ignition, but this condition is

not absolutely essential to competition, and the OSC will be prepared to

consider mechanical arrangements for capping, as well as systems

capped in the ordinary manner.

10. Lubrication - Wax on bullets. This is indispensable; but any other

lubricant may be superadded or applied to the cartridge, if thought

necessary by the competitor.

In response to the advertisement, twenty-four specimen arms were submitted. These were the Albini, the Aston, the Byrnes and Benjamin, the Carle, the Carr, the Craig, the Della Noce, the Henry, the Hughes, the Joslyn, the Lindner, the Luok, the Mathews, the Millar (two types), the Needham (two types), the Norris, the Peabody, the Poppenburg, the Shepard (two types), the Snider, and the Timmerhans. Of these, only eight were in conformity to the caliber, weight, and other specifications noted in the advertisement. Of these eight, four systems were selected for trial: The Snider, the Joslyn, the Henry, and the Lindner. Of the four, the Snider system was deemed to be the only one approaching the standards required for infantry armament, and it was adopted as a conversion for existing stocks of Enfield rifle-muskets. It was not, however, considered further for selection as the true breech loading rifle being sought.

While the Snider was being adopted, the OSC remarked that several prominent gunmakers had declined to answer the advertisement. It was thought that these manufacturers had been deterred by the short lead time allowed for the preparation of specimen arms. This apparent lack of interest in the gunmaking community induced the War Office to hold a conference on the matter on November 28, 1865. It was decided that a questionnaire would be sent to a number of selected gunmakers, regardless of their participation in the previous competition, to get their opinions on the feasibility of producing a breech loading rifle of .450 caliber, using self-primed ammunition and fit for service use. The questionnaire, dated December 18, 1865, contained three questions:

Question 1

Referring to the advertisement of 21st June, 1865, of which a copy is enclosed, will you be good enough to state for Lord de Grey's consideration, whether there is anything in its terms or nature which had the effect of deterring you, or is likely to have deterred other leading gunmakers, from taking part in the proposed competition for the production of a small bore breech loading military rifle; and if so, will you point out in what respect you think the terms of the advertisement open to amendment?

If the Secretary of State should decide on issuing a fresh advertisement, what, in your opinion, is the least time that should be allowed -(1) For the preparation of the specimen for submission to the committee?

(2) For the subsequent production of six rifles, to be submitted for trial if that system is admitted to the competition?

Are there, in your opinion, any insuperable difficulties in the production of a breech loading arm for general military use with cartridges containing their own ignition? Could such a cartridge be satisfactorily used with a bore of 0.45-inch, or what is the smallest caliber with which you would think that such cartridges could be employed?As a result of the replies received from the inquiry, a new competition was opened on October 22, 1866, with each accepted competitor to paid £300 to cover the cost of the six trials rifles, and a prize of £1,000 for the best rifle submitted, £600 for the best breech mechanism, £400 for the best cartridge. The specifications laid down by the new competition were as follows:

A) Weight - Not to exceed 9lbs, 5ozs without bayonet.On June 11, 1867, the prize sub-committee of the OSC reported that 104 rifles had been submitted for examination. Of those, 37 were in compliance with the terms of the advertisement, 67 had not complied, and while ineligible for the competition were set aside for consideration on their own merits. Further consideration of the 37 complying rifles, resulted in the rejection of 28. The nine systems to be carried over for trial, and requiring six specimen arms were the Albini & Braendlin, the Burton No.1 and No. 2, the Fosbery, the Henry, the Joslyn, the Martini, the Peabody, and The Remington.

B) Length - To be 51 inches, with short stock, measured from the hollow

of butt plate to the muzzle.

C) Weight of ammunition made up - Must not exceed 6lbs 4ozs for 60

rounds as packed for service.

D) Cartridges - Must carry their own ammunition.

E) Sights - The foresight must be such as to admit of a bayonet being fixed

according to the present system.

F) Stock - Must be such as to carry a light metal cleaning rod, and allow a

sling to be used.

G) Recoil - Must not exceed that of the Enfield rifle by more than 10

percent.

H) The arm as a whole - Must be as little liable to injury by long continued

firing, rough usage, and exposure, as the naval rifle converted to a

breech loader on the Snider system. To be capable of being used

without accident by imperfectly trained men, and of being manufactured

in quantities and of uniform quality.

I) The ammunition as a whole - Must be as little liable to injury by rough

usage, damp, and exposure in all climates as the Boxer cartridge for

Snider's converted Enfield rifle; also as little liable to accidental explosion

as the same cartridge, and as capable of being manufactured in large

quantities of uniform quality.

K) Calibre - Optional

L) The twist and form of groove - Optional

M) The lock - Optional

N) Rapidity of fire - Capable of firing at least twelve rounds per minute

without aiming, the cartridges being arranged on a table.

O) Accuracy when fired from a fixed rest - The arm must give a mean figure

of merit of not more than 36 inches at 1,000 yards.

P) Trajectory - Not to require at 500 yards an elevation of more than 1

degree 30 minutes.

Q) Fouling - The shooting not to deteriorate more than 20 percent at 1,000

yards, after 250 rounds.

R) Penetration - The mean penetration of five shots not to be less than that

of the present service muzzle loading Enfield rifle, viz, 12 half-inch elm

planks, which have been soaked 48 hours in water. Distance 30 yards.

S) Lubrication - Wax on bullets is indispensible, but any other lubricant may

be superadded or applied to the cartridge, if though necessary by the

competitor.

From top: Martini, Peabody, and Henry Prize Competition Rifles. Image credit: Temple, B.A. and I.D. Skennerton, A Treatise on the British Military Martini: The Martini-Henry 1869-C1900, INPRINT, Brisbane, Queensland, Australia, 1983, Page 10 |

All rifles attained the requisite rate of fire.In presenting the results of the competition, the OSC noted that none of the rifles had fulfilled the requirements of the competition, and consequently none of the inventors had claim to the £1,000 prize. The competing designs were ranked as follows:All rifles produced the required recoil force or less.

Five out the the nine, as well as the Snider, failed to penetrate the required number of planks.

In trajectory, three, in addition to the Snider, qualified.

In fouling, only two rifles and the Snider, qualified.

All rifles passed the rough handling tests.

All but two stood the overpressure tests.

1. Henry

2. Burton

No. 2

3. Albini

& Braendlin

4. Fosbery

5. Burton

No. 1

6. Peabody

7. Martini

8. Remington

9. Joslyn

With respect to the best breech mechanism, the £600 prize was awarded for the Henry breech, with the comment that "the breech mechanism combines strength, safety and simplicity; the extractor works with remarkable regularity, and the arm can be fired with great ease and rapidity, and is not affected by rough usage." The chief defect of the Martini was attributed to faulty ammunition. The committee expressed regret that no new service arm resulted from the competition.

As a result of the competition, the OSC decided to try a new tack. The components of the new rifle were to be decided upon individually. The breech system was to be decided by an open competition of all the systems that either had been or could be brought to test. The barrel was to be confined to systems that had given the best results as muzzle loaders - the Henry, Lancaster, Metford, Rigby, Westley Richards, Whitworth, and Enfield. The barrel was stipulated as 35" in length, 4lbs 6ozs, and of .45 caliber. The bullet was to be 480 grains in weight propelled by a powder charge of 85 grains. The case was to be the government boxer case, and lubrication was to be pure beeswax.

The barrel trials were concluded with the OSC report dated February 11, 1869. The Henry .45 caliber barrel had shown a marked superiority over all other competitors, and especially against the Snider .50 and .577 caliber barrels which were the current service arms. In all respects (accuracy, trajectory, effects of wind, fouling, and penetration) the Henry barrel was superior to all others. The only place the Henry barrel fell short of the Snider was in the form of the cartridge, it being felt that the longer .45 caliber cartridge would be more susceptible to damage than the others. However, the cartridge was still considered amply durable for service usage.

The breech trials were conducted as follows: All breech actions submitted were carefully examined, and those that were approved were to have 20 shots fired for rapidity. Sand was then thrown over the action, in both open and closed states and the rifle fired without any cleaning except for what could be done with the hand. Three cartridges, intentionally damaged so as to ensure an escape of propellant gas, were then fired to test the action's safety with defective ammunition. If the action passed all these tests, it was put through a course of continual firing, and was allowed to rust at intervals between the days of firing. After the initial inspection, a candidate list was proposed. The candidate actions fell into two broad categories, the block and the bolt.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All rifles were deemed to have shown a sufficient degree of rapidity of fire, with the Bacon being the fastest, dispensing all rounds in 58 seconds and the Wilson in one minute 26 seconds. No rifles were affected by the damaged cartridge test, save for the Bacon, which had its extractor blown away. All the rifles passed the sand test. The exposure test was conducted in a most interesting manner. One hundred rounds were fired on four consecutive days, and the rifles were then left in the open air exposed to natural precipitation. If no natural precipitation was present, water was applied artificially, with the actions alternately open and closed. The rifles were then left uncleaned for another three to four days, and were fired to see if they were still serviceable.

After examining the results of the trials, the OSC immediately rejected the Berdan, the Money-Walker, and the elevating block Westley-Richards. Of those remaining, the Henry and the Martini were considered to be by far the best. Of these, the Martini gave the best results in the endurance trials, and demonstrated that its faults in the second competition had been due to defective ammunition. The Martini action was then retested with longer, loose powder service cartridges. In this test, 20 rounds were fired in 53 seconds, and after another exposure test, 20 rounds were fired in one minute 3 seconds, with the action working as smoothly as it had before. In the final analysis, the OSC gave preference to the Martini action, and recommended it as the one best qualified for a military arm of any that had been presented.

Now that the barrel and breech had been selected, the task was to mate the two. Two assembled rifles were received by the OSC in January 1869. The rifles were fired for accuracy at 300, 500, 800, 1000, and 1200 yards, and the trajectories ascertained. During these trials, it was discovered that a seven groove Henry barrel gave accuracy as good as the nine groove type tested in the trials, and gave a lower trajectory. The guns were fired for endurance. No dimensional change was noted in any of the parts after 2,100 rounds, and after 3,000 rounds, the rifle was working as smoothly as it had with the first rounds fired. After the tests were concluded, the OSC, in a report dated February 11, 1869 stated that in the event of the arm being adopted into service, it should be called the Martini-Henry.

OPERATION

and DESIGN

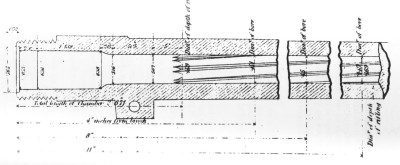

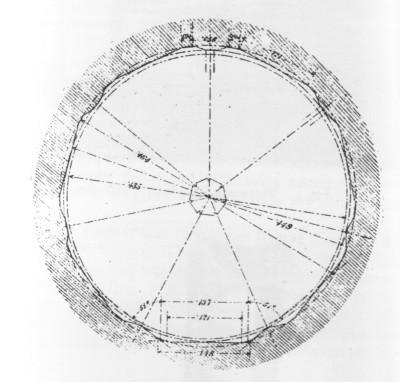

Much of the

Martini-Henry's prodigious reputation for accuracy can be attributed to

Henry's rifling, which was the result of years of experimentation and adaptation

from the basics laid down by Joseph Whitworth. As issued, the Henry

barrel had a nominal bore of 0.450" obtained by allowing an 0.449" plug

to run while rejecting a plug of 0.451". The bore was slightly enlarged

at the breech so that a 0.451" plug would run in about four inches from

the breech and one of 0.450" about eight inches. From that point

the the muzzle, the bore was cylindrical. The grooves in the tapering

section were .009" deep to within an inch of the true bore, and from there

to the muzzle about .007" deep. There were seven grooves of a right

hand uniform twist of one turn in 22". The chamber was cut in the

barrel and was coned .018" to aid in extraction. British Patent No.

2802 of 1860 covered this rifling and described it as a polygonal bore,

the angles of which were broken by ribs and which created re-entering angles,

the inscribing circle tangential to the ribs being described with the same

radius as the inscribing circle tangential to the plane sides. This

meant that the .030" wide middle portion of the grooves and the .010 wide

tops of the ribs which formed the lands were part of the original bore

of .450". The grooves were not quite flat, but had gently sloping

sides.

Henry Rifling, Longitudinal View |

Henry Rifling Cross-Section |

The action consists of a body or shoe (the receiver), into which the barrel is

Image credit: Temple, B.A. and I.D. Skennerton, A Treatise on the British Military Martini: The Martini-Henry 1869-C1900, INPRINT, Brisbane, Queensland, Australia, 1983, Page 117 |

screwed. The butt and fore-end are also attached to the body. Inside the body is the breech block and its associated control mechanisms. The breech is sealed by a block which swings on a pin passing through the upper rear of the body. The recoil is absorbed by the back and side of the body, and not the pin. The primer is detonated by a striker driven by a spring within the breech block. A lever in the back of the trigger acts upon the breech block by means of two horns, so that when the lever is lowered the block falls and strikes the lower arm of the extractor, ejecting the spent case. With the same motion, the lever carries the L shaped tumbler until the trigger nose falls into the bent of the tumbler, and retains it in the cocked position. The lever action also draws back the striker and compresses the mainspring by means of the upper portion of the tumbler which engages in a slot cut through the striker. When the lever is returned to the upper position, the breech block is |

Developments in ammunition led to the introduction of a "short" round, carrying the same powder charge as the longer .45 caliber round used in the competition. This was actually a bottlenecked case which gave the advantages of a shorter and lighter breech action, greater facility of loading, and a shorter and stronger cartridge.

Finally, after years of exhaustive testing, the short-actioned (i.e. chambered for the bottle neck .577/.450 cartridge) Martini-Henry rifle, weighing 8lbs 7.5ozs was adopted for land service on March 30, 1871. The Martini-Henry was to soldier on on British service for almost 30 years, in various marks and configurations, proving to be one of the finest long arms ever issued to any military force.

BIBLIOGRAPHY

Temple, B.A., and I.D. Skennerton, A Treatise on the British Military Martini: The Martini-Henry 1869-C1900, (INPRINT, Brisbane, Queensland, Australia: 1983)

A Treatise

on the British Military Martini is available from IDSA Books.

Click on the image to order: